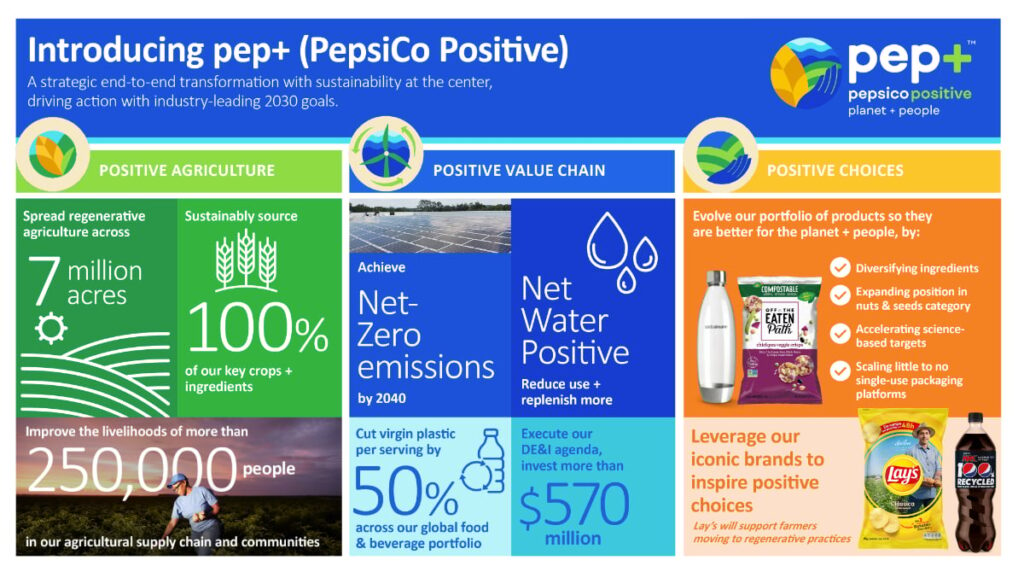

PepsiCo: 40% fewer returns, union realignment

Client: PepsiCoSector: Consumer Goods / Beverage DistributionRegion: Midwest U.S. Problem:High damage returns, inventory discrepancies, and union-management friction threatened delivery reliability. Solution:Negotiated new union contract with productivity KPIsImplemented Lean Six Sigma in high-volume DCsRolled out Just-in-Time shipping Results:Damage returns dropped 40%Labor productivity rose 28%Union stability with long-term KPI tracking

Ford: Multi-plant shutdown prevention, 90% SAP error reduction

Client: Ford Motor CompanySector: Automotive ManufacturingRegion: Kansas City (MO), Louisville (KY), Ontario (Canada) Problem:Recurring facility shutdowns due to part shortages from supplier Rula Bula, caused by SAP mismanagement and lack of production buffers. Solution:Re-trained teams on SAP inventory usageBuilt time studies + buffer cycle designScaled coordinated ops across 3 regions Results:Eliminated shutdowns at all plantsReduced […]

McKesson: 100% milestone completion, 3% under budget

Client: McKessonSector: Healthcare / PharmaceuticalRegion: Northern NJ & Northern VA Problem:Facility launches were failing to meet budgets or timeline milestones. Projects ran 18% over budget with no major milestones achieved. Solution:Deployed proactive staffing plans ahead of launchRan SKU flow simulations to model inventory demandAutomated inventory control and selection systems Results:Achieved 100% milestone completionCame in 3% […]